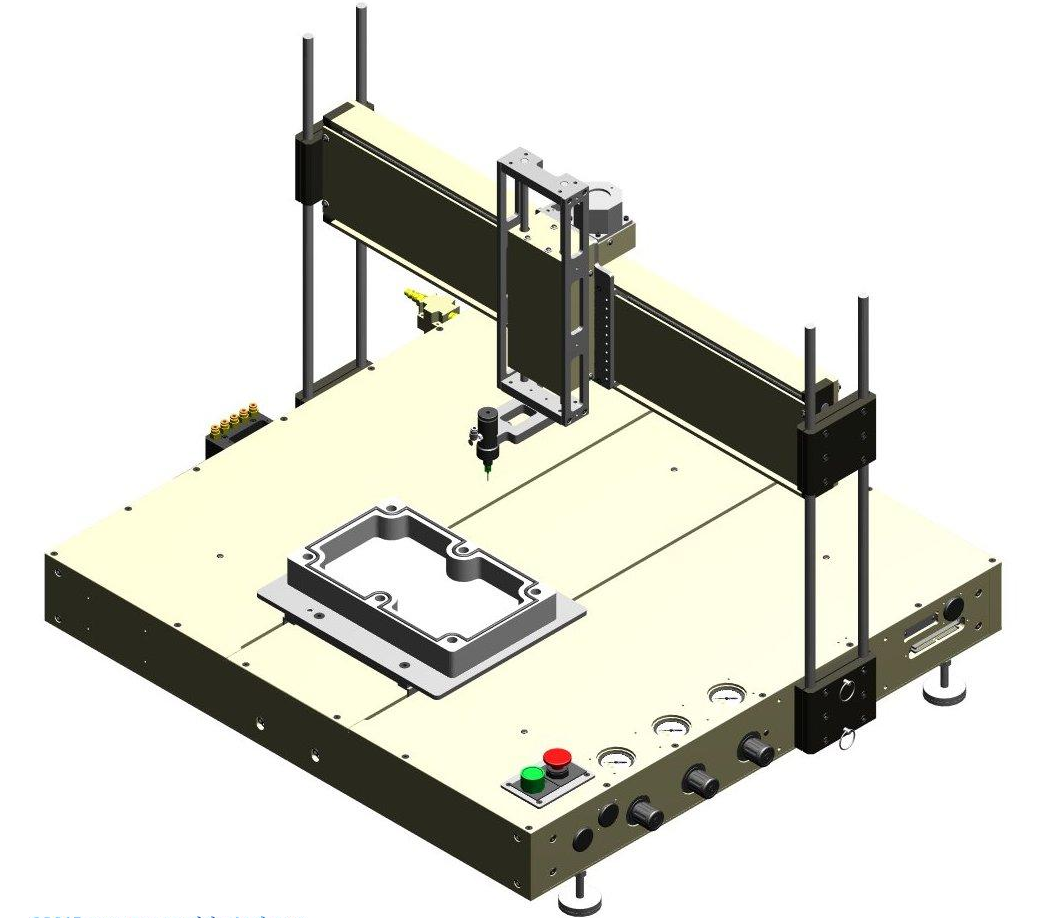

The CP24 is our larger 24×16 work area base

High Speed Hotmelt

At 24 inches per second of travel, this CP24 yields terrific throughput! The head dispenses "pats" of hotmelt PSA adhesive to help fixture products on a plastic sheet. The sheets are held on with a vacuum system that detects when a sheet has been removed and when a new sheet has been placed on the pallet. The high speed and the vacuum system combine to yield a throughput rate of less than eight seconds per sheet!

Compliant Foot Gasket Dispensing

New Precision Technology has developed in-house a new standoff foot dispensing technique designed to deal with part height variation as a production issue. While the basic standoff foot technique has been with us for quite some time for precision dot dispensing, it is normally considered impossible to dispense a closed shape (circle, square, etc) using this method as the foot will run through the gasket at some point. To address this, we rotate the part, which prevents potentially messy dispense valves from being complicated with rotational hardware. This technique lends itself to precision gasket formation for fuel cells, LCD screens, display terminals, and any flat structures requiring precision gaskets or adhesive seals.

Vertical Wall Gasket Dispensing

With a theta mounted on the Z axis, it becomes possible to accurately dispense gaskets along the vertical walls of objects. In this example we have machined sockets which require a seal at the entry point. By itself this is not a difficult concept. The difficulty in doing this kind of thing in production lies with the issue of tip calibration. Using a unique calibration process that definitively locates the dispense tip no matter the tip angle or length of arm from center of rotation, New Precision Technology has simplified this technique, making it a production-friendly process.

Moisture cure RTV gasket dispensing

Moisture cure RTV materials have certain strengths that make them an important player in the gasketing world. Unlike UV cure gasket compounds that cure virtually instantly upon exposure to UV, moisture cures can take several hours before they can be handled and they require a little more maintenance than UV cure materials as well - it's more difficult to keep humidity away from a moisture cure than it is to keep UV away from a UV cure! On the plus side, they do not have to be translucent like many UV cures (unless you have a dual UV/moisture cure like Loctite 5950) and this allows some unique properties - ones that enable silicones to survive in the engine compartment with high heat and oil contact. Also on the plus side: they tend to be far less costly than their UV cure counterparts!