Hot melt applications are cost effective solutions to assembly process difficulties. Rapid dispensing coupled with low cost adhesives, provides excellent return on investment.

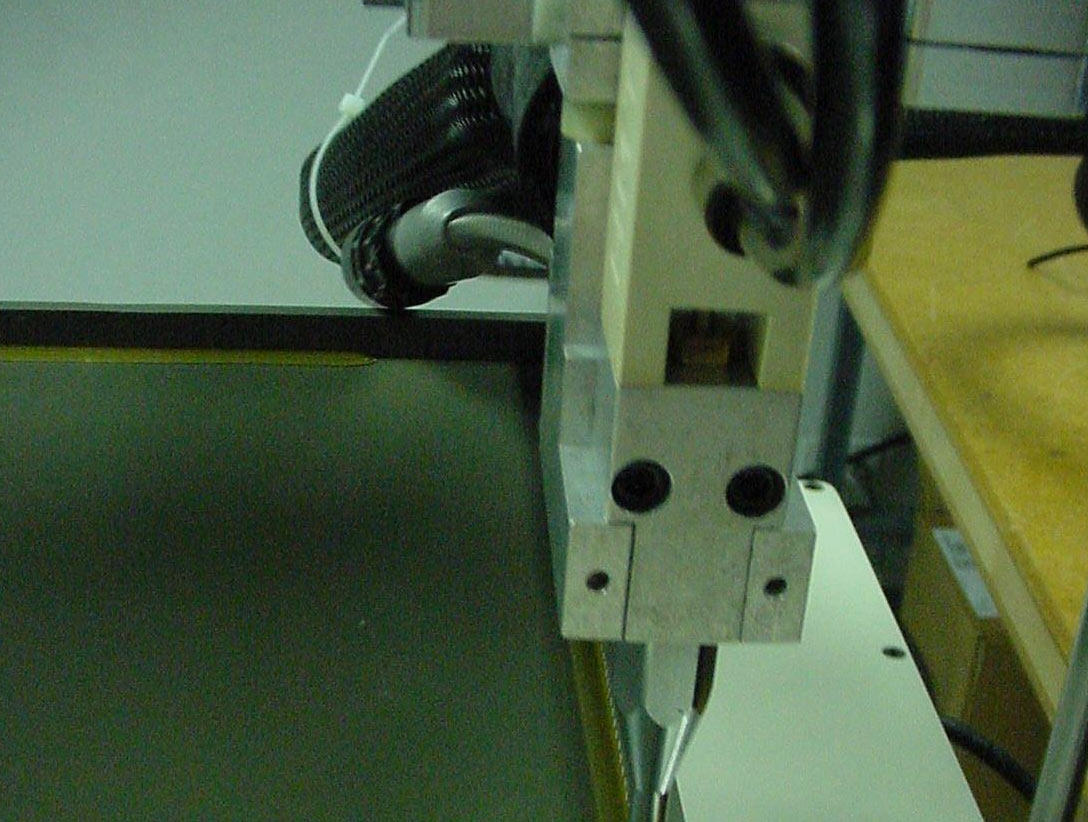

Because of the high temperatures seen by the head (temperatures that would otherwise damage the motion components of the robot) excellent heat isolation is necessary. While our examples may show an open head design for clarity, heads are shrouded when in production.

At 24 inches per second of travel, ourCP24 yields terrific throughput! The head dispenses “pats” of hotmelt PSA adhesive to help fixture products on a plastic sheet. The sheets are held on with a vacuum system that detects when a sheet has been removed and when a new sheet has been placed on the pallet.

The high speed and the vacuum system combine to yield a throughput rate of less than eight seconds per sheet!